Injection Mold Design – Practical Engineering Knowledge

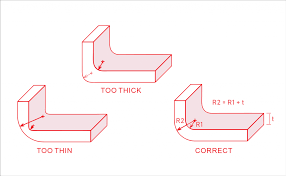

1. Part Geometry & Wall Thickness

Early evaluation of part geometry helps identify thin sections, ribs, and tolerance-critical features. Uniform wall thickness improves flow behavior and reduces warpage.

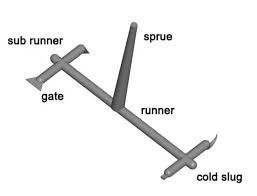

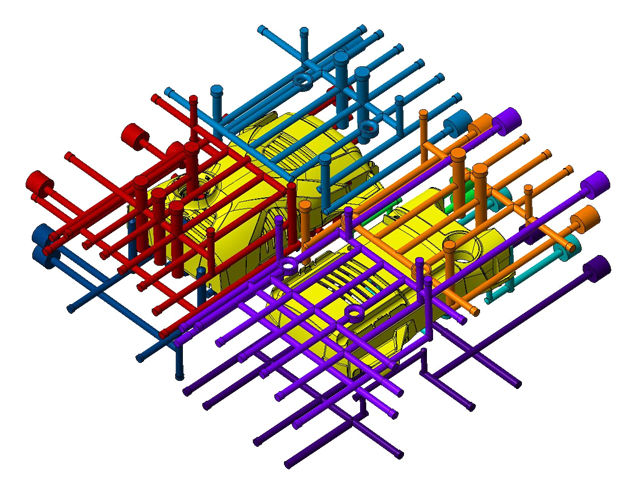

2. Gate & Runner Design

Gate location and runner balance affect filling, weld lines, and surface quality. Gate selection depends on material and part geometry.

3. Cooling System Design

Proper cooling channel placement reduces cycle time and improves dimensional stability by maintaining uniform mold temperature.

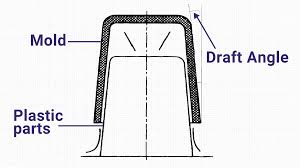

4. Draft Angles & Ejection

Adequate draft and correct ejector layout ensure smooth part release without deformation or surface damage.

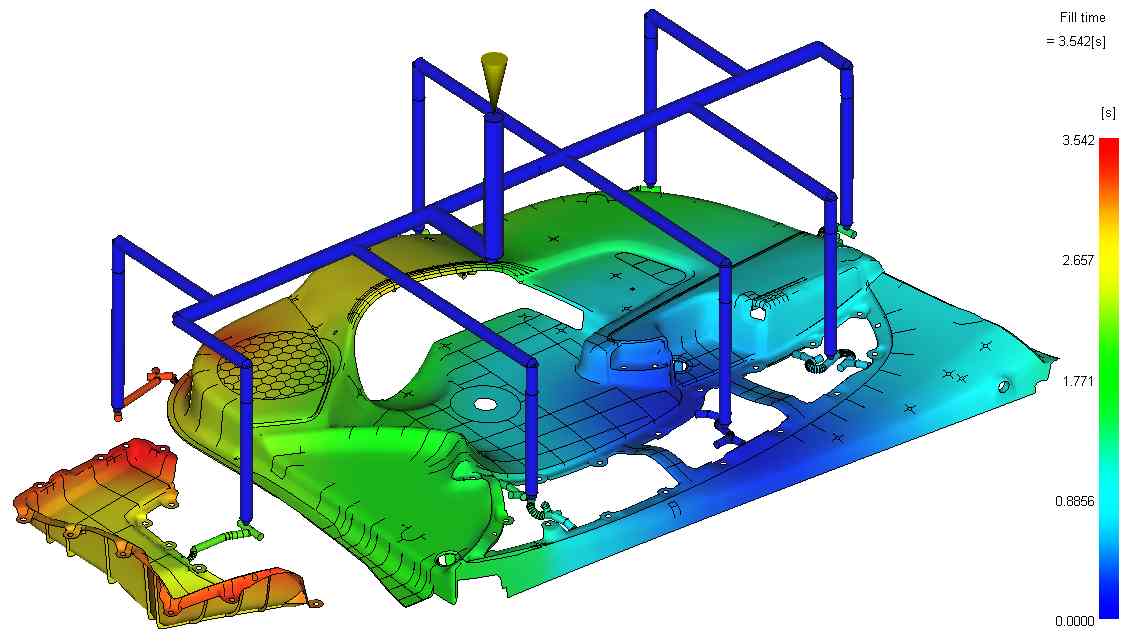

5. Mold Flow Analysis

Mold flow analysis helps predict filling behavior, pressure demand, and potential defects before tool manufacturing.